0102030405

The Versatility of PTFE Pall Rings in Chemical Processing

2024-05-14 00:10:00

In the world of chemical processing, efficiency and effectiveness are key factors in ensuring the success of operations. One crucial component that plays a significant role in this industry is the PTFE Pall Ring. These innovative and versatile pieces of equipment have revolutionized the way chemical processing is carried out, offering a wide range of benefits and applications.

PTFE Pall Rings are a type of random packing used in chemical processing towers and columns. They are designed to provide a large surface area for gas and liquid contact, promoting efficient mass transfer and separation processes. The unique design of the Pall Ring allows for high void fractions and low pressure drops, making them ideal for a variety of applications in the chemical industry.

One of the key advantages of PTFE Pall Rings is their exceptional chemical resistance. PTFE, or polytetrafluoroethylene, is a synthetic fluoropolymer that is known for its inertness and resistance to a wide range of chemicals and solvents. This makes PTFE Pall Rings suitable for use in corrosive environments and with aggressive chemical compounds, where other materials may fail or degrade over time.

The high thermal stability of PTFE Pall Rings further enhances their suitability for use in demanding chemical processing applications. With a continuous service temperature range of -200°C to 260°C, PTFE Pall Rings can withstand extreme heat and maintain their structural integrity, making them a reliable choice for high-temperature processes.

In addition to their chemical and thermal properties, PTFE Pall Rings are also known for their excellent mechanical strength and durability. Their robust construction allows them to withstand the rigors of industrial operations, ensuring long-term performance and reliability. This durability translates to cost savings for chemical processing facilities, as the need for frequent replacements or maintenance is minimized.

The versatility of PTFE Pall Rings extends beyond their chemical resistance and mechanical strength. These packing materials are also designed to provide high mass transfer efficiency, making them suitable for a wide range of separation and purification processes. Whether it's distillation, absorption, or stripping, PTFE Pall Rings can enhance the performance of chemical processing equipment, leading to improved productivity and product quality.

Furthermore, PTFE Pall Rings are available in various sizes and geometries, allowing for customization to meet specific process requirements. This flexibility in design enables engineers and operators to optimize the performance of their chemical processing equipment, tailoring the packing configuration to achieve the desired separation and mass transfer outcomes.

The use of PTFE Pall Rings in chemical processing also aligns with sustainability and environmental considerations. By improving the efficiency of separation processes, these packing materials contribute to reduced energy consumption and waste generation, ultimately supporting the industry's efforts towards more sustainable practices.

In conclusion, PTFE Pall Rings have become indispensable components in the field of chemical processing, offering a combination of chemical resistance, thermal stability, mechanical strength, and mass transfer efficiency. Their versatility and reliability make them a preferred choice for a wide range of applications, from petrochemical refining to pharmaceutical production. As the industry continues to evolve, PTFE Pall Rings will undoubtedly remain at the forefront of innovation, driving advancements in chemical processing technology.

PTFE Ring and Packing

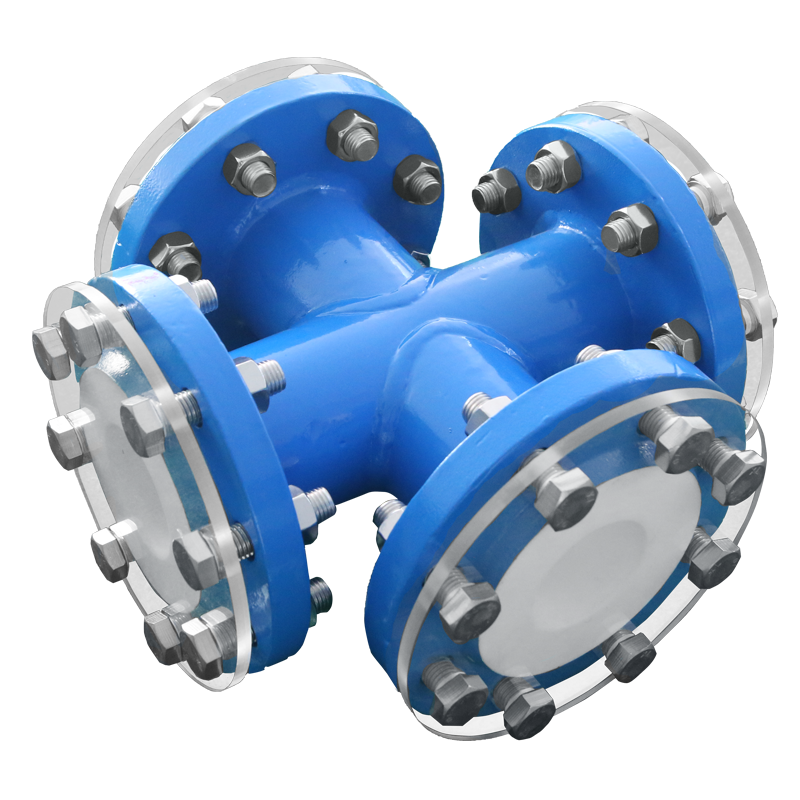

PTFE Ring and Packing PTFE Lining Steel Pipes and Fittings

PTFE Lining Steel Pipes and Fittings PTFE Lined Vessels and Packing

PTFE Lined Vessels and Packing PTFE Sheet

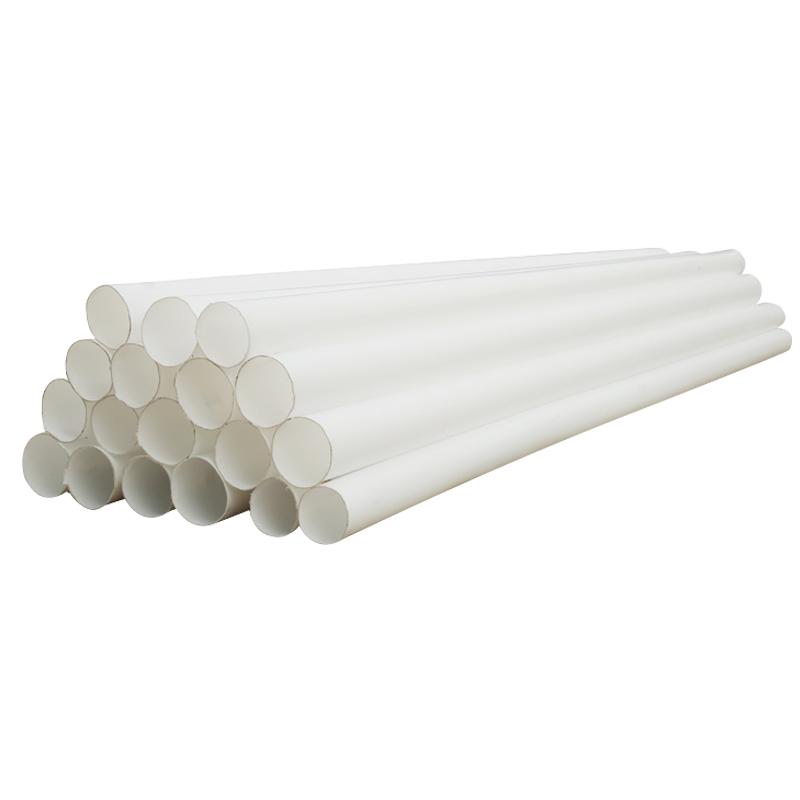

PTFE Sheet PTFE Pipe

PTFE Pipe PTFE Lined Steel Pipe/Tube

PTFE Lined Steel Pipe/Tube