0102030405

The Benefits of PTFE Lined Reducers in Industrial Applications

2024-05-22 00:08:35

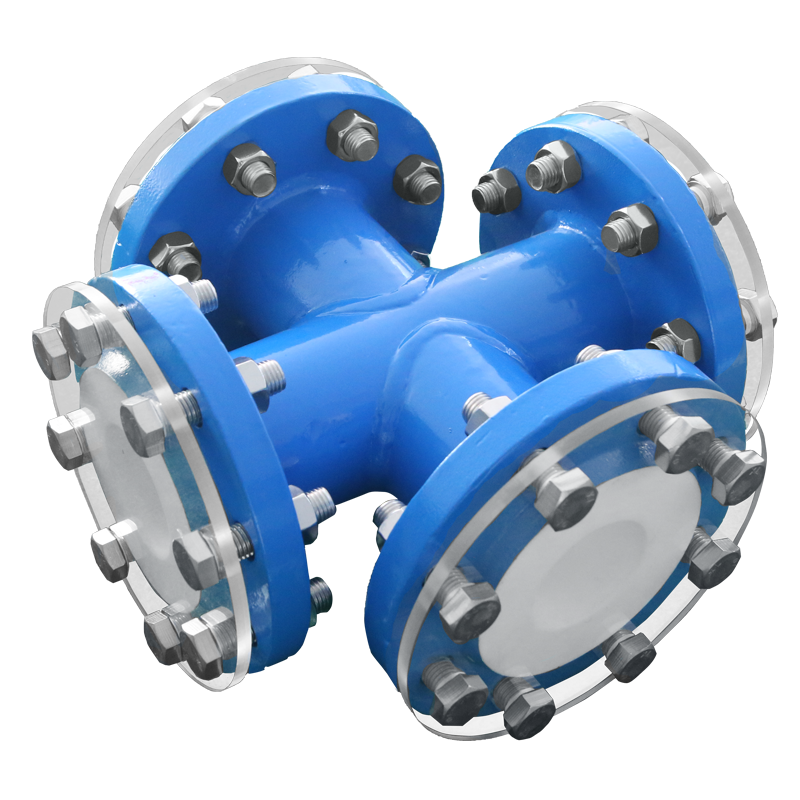

In the world of industrial processing, the use of high-quality components is essential to ensure efficiency, safety, and longevity. One such component that plays a crucial role in various industrial applications is PTFE lined reducers. These reducers are designed to provide a seamless transition between different pipe sizes while offering the exceptional chemical resistance and non-stick properties of PTFE (polytetrafluoroethylene). In this blog, we will explore the benefits of PTFE lined reducers and their significance in industrial settings.

Chemical Resistance

One of the primary advantages of PTFE lined reducers is their exceptional chemical resistance. PTFE is known for its inertness and ability to withstand a wide range of corrosive chemicals, making it an ideal choice for handling aggressive substances in industrial processes. By lining reducers with PTFE, manufacturers can ensure that the components are well-protected against the damaging effects of acids, bases, solvents, and other corrosive materials. This resistance to chemical attack helps to prolong the service life of the reducers and minimizes the risk of leaks or failures in the system.

Non-Stick Properties

Another key benefit of PTFE lined reducers is their non-stick properties. PTFE is inherently non-stick, which means that it resists the adhesion of materials to its surface. In industrial applications where the flow of viscous or sticky substances is common, such as in the food processing or pharmaceutical industries, PTFE lined reducers help to prevent build-up and clogging, thereby maintaining smooth and uninterrupted flow within the piping system. This non-stick characteristic also simplifies cleaning and maintenance, as the reduced likelihood of material build-up minimizes the need for frequent cleaning and ensures efficient operation.

Temperature and Pressure Resistance

PTFE lined reducers are capable of withstanding a wide range of temperatures and pressures, making them suitable for use in diverse industrial environments. Whether it's high-temperature steam, cryogenic fluids, or high-pressure gases, PTFE lined reducers offer reliable performance under challenging conditions. This versatility allows for their use in various industries, including chemical processing, petrochemical, pharmaceutical, and food and beverage, where the operating conditions can be demanding.

Corrosion Resistance

In addition to chemical resistance, PTFE lined reducers also provide excellent corrosion resistance. Corrosion can be a significant concern in industrial settings, as it can compromise the integrity of piping systems and lead to costly repairs and downtime. By incorporating PTFE lining, reducers are effectively shielded from the effects of corrosion, ensuring that they maintain their structural integrity and performance over time. This corrosion resistance is particularly valuable in applications where the piping system is exposed to harsh environments or aggressive substances.

Versatility and Customization

PTFE lined reducers are available in a range of sizes and configurations to accommodate different piping requirements. This versatility allows for the customization of reducers to suit specific applications, ensuring a precise fit and seamless integration within the piping system. Whether it's a reduction in pipe diameter or the need to connect pipes of different sizes, PTFE lined reducers offer a flexible solution that can be tailored to meet the unique needs of various industrial processes.

In conclusion, PTFE lined reducers offer a host of benefits that make them indispensable in industrial applications. From their exceptional chemical resistance and non-stick properties to their ability to withstand temperature and pressure variations, PTFE lined reducers contribute to the efficiency, reliability, and longevity of piping systems in diverse industries. By choosing high-quality PTFE lined reducers, industrial operators can ensure the smooth and safe operation of their processes while minimizing the risk of corrosion, material build-up, and system failures. As a result, PTFE lined reducers play a vital role in maintaining the integrity and performance of industrial piping systems, making them a valuable investment for any industrial operation.

PTFE Ring and Packing

PTFE Ring and Packing PTFE Lining Steel Pipes and Fittings

PTFE Lining Steel Pipes and Fittings PTFE Lined Vessels and Packing

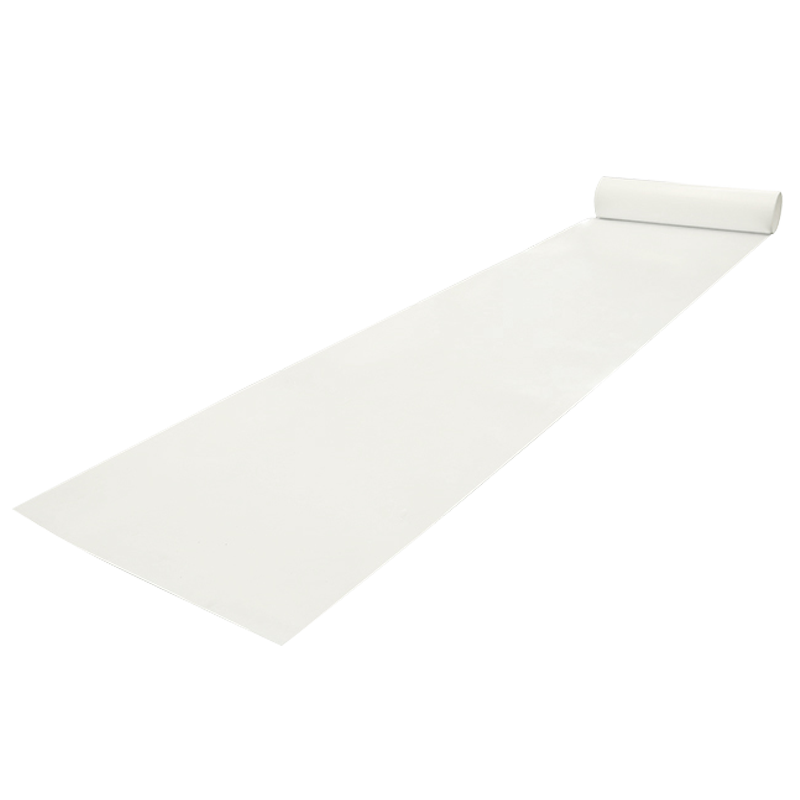

PTFE Lined Vessels and Packing PTFE Sheet

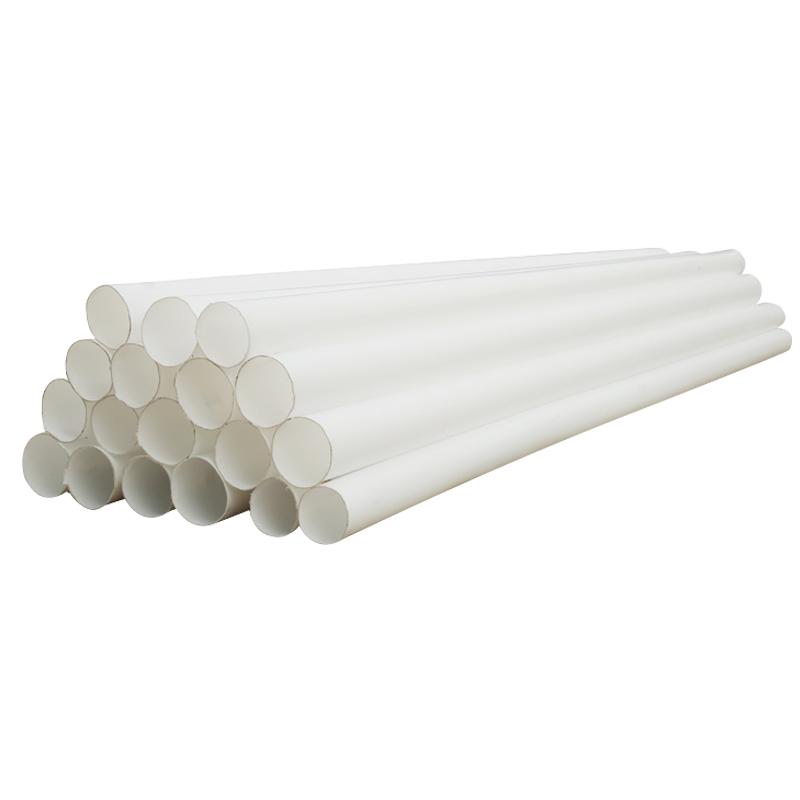

PTFE Sheet PTFE Pipe

PTFE Pipe PTFE Lined Steel Pipe/Tube

PTFE Lined Steel Pipe/Tube