PTFE plate is made of 100% pure polytetrafluoroethylene by molding, turning, cutting and other processes. It has the best chemical resistance in known plastics, no aging, electricity Insulated with a very low coefficient of friction, can be used at temperatures from -180 to +260 degrees without load. Suitable for sealing materials such as flat pad, V-shaped pad, lining material, lubricating materials such as piston rings and guide rails, electrical insulating materials, anti-adhesive materials, etc.

Polytetrafluoroethylene sheet (also called PTFE plate, Teflon sheet, Teflon sheet) is divided into two types: die-casting and turning. The molded plate is formed by molding with a polytetrafluoroethylene resin at room temperature, and then sintered. Made by cooling. The PTFE turning board is formed by pressing, sintering and rotary cutting of polytetrafluoroethylene resin. Its products are widely used and have excellent comprehensive performance: high temperature resistance (-192°C-260°C), corrosion resistance (strong acid, strong alkali, aqua regia, etc.), weather resistance, high insulation, high lubrication, no adhesion, Excellent characteristics such as no toxicity.

PTFE plate is mainly used as lining, supporting slider, rail seal and lubricating material for electrical insulating materials and contact corrosive medium. It is widely used in chemical, pharmaceutical, dye industry containers, storage tanks, reaction tower kettles, large pipelines. Anti-corrosion lining materials; machinery, construction, traffic bridge sliders, guide rails; printing and dyeing, light industry, anti-adhesive materials for the textile industry.

Process parameters:

Raw material treatment: mash through 10~20 mesh sieve, and place it in the environment of 23 °C ~ 25 °C for 24h ~ 48h for temperature adjustment.

Molding: pressure 1715 ~ 35MPa, holding time 1 ~ 10min.

Sintering: sintering temperature 360 °C ~ 380 °C, heating rate 30 °C / h, 330 °C for 2h, 370 °C for 3h.

Cooling: The cooling rate is 20 °C / h, and it is slowly cooled at around 330 °C near the melting point of PTFE.

Major equipment:

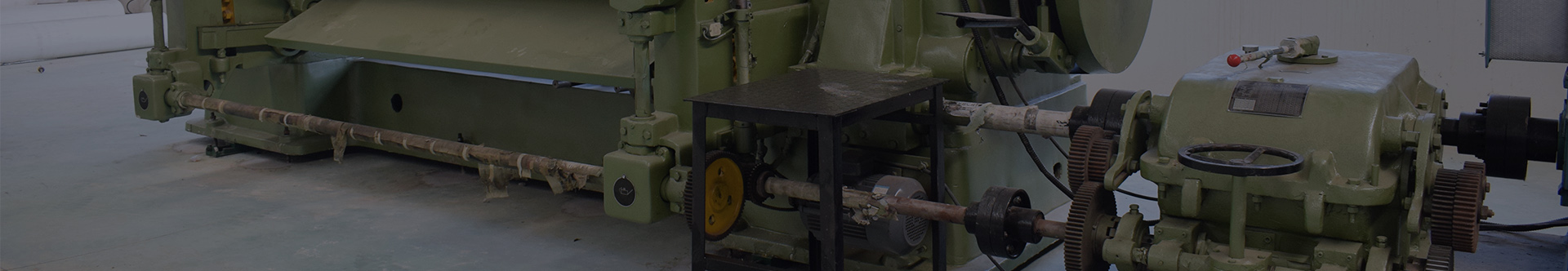

YJ79 — 3500 engineering plastic hydraulic press

DL—88A large sintering furnace

Post time: Apr-15-2022