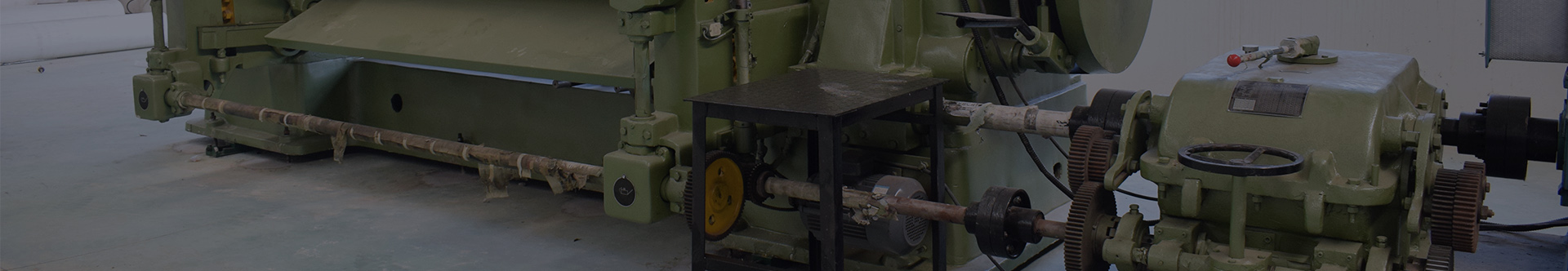

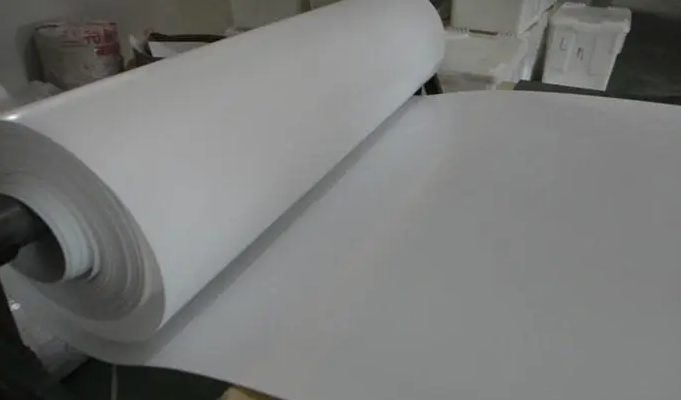

Turning plate

PTFE turning plate is made of PTFE resin through compaction, sintering and rotary cutting machine. Generally speaking, the thickness of PTFE turning plate is 0.5mm-12mm .

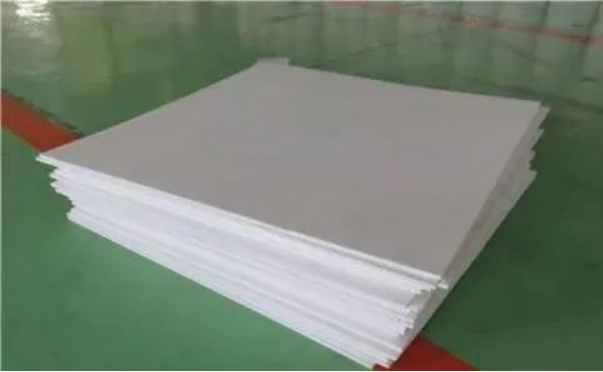

Molded plate

The molded plate is made of polytetrafluoroethylene resin by molding at room temperature, and then sintered and cooled, and the thickness of the PTFE molded plate is 5mm-200mm .

Stair board

PTFE stairs are processed by extrusion or turning process. Because of their excellent sliding properties, reliable strength and strong elongation, they are often used in stair sliding bearings, supporting sliders, guide rails, etc.

Of course, the PTFE products produced by any process are very versatile and have extremely superior comprehensive properties. Mainly used as electrical insulation materials and linings in contact with corrosive media, supporting sliders, rail seals and lubricating materials, widely used in chemical, pharmaceutical, dye industry containers, storage tanks, reaction towers, large pipelines anti-corrosion lining materials; Machinery, construction, traffic bridge sliders, guide rails; printing and dyeing, light industry, textile industry anti-sticking materials, etc.

Advantage:

High temperature resistance - operating temperature up to 260 ℃.

Low temperature resistance - good mechanical toughness; 5% elongation can be maintained even when the temperature drops to -196 °C.

Corrosion resistance - inert to most chemicals and solvents, strong acid and alkali resistance, water and various organic solvents.

Weather Resistant - Has the best aging life of any plastic.

High Lubrication - The lowest coefficient of friction among solid materials.

Non-adhesion - is the smallest surface tension in solid materials, does not adhere to any substance, and its mechanical properties have a very small friction coefficient, only 1/5 of polyethylene , which is an important feature of perfluorocarbon surfaces. And because the fluorine - carbon chain intermolecular force is extremely low, PTFE is not sticky.

Non-toxic - It is physiologically inert, and it has no adverse reactions when it is implanted in the body as an artificial blood vessel and an organ for a long time.

Electrical properties PTFE has low dielectric constant and dielectric loss over a wide frequency range, and high breakdown voltage, volume resistivity and arc resistance.

Radiation resistance The radiation resistance of PTFE is poor ( 104 rad), and it is degraded by high-energy radiation, and the electrical and mechanical properties of the polymer are significantly reduced. Application Polytetrafluoroethylene can be processed by compression or extrusion; it can also be made into an aqueous dispersion for coating, impregnation or fiber making. PTFE is widely used in atomic energy, aerospace, electronics, electrical, chemical, mechanical, instrument, instrument, construction, textile, food and other industries as high and low temperature resistant, corrosion resistant materials, insulating materials, anti-stick coatings, etc.

Atmospheric aging resistance: radiation resistance and low permeability: long-term exposure to the atmosphere, the surface and performance remain unchanged.

Incombustibility: The oxygen limit index is below 90 .

Acid and alkali resistance: insoluble in strong acids, alkalis and organic solvents.

Oxidation resistance: can resist the corrosion of strong oxidants.

Acidity and alkalinity: Neutral.

The mechanical properties of PTFE are relatively soft. Has very low surface energy.

Polytetrafluoroethylene (F4, PTFE) has a series of excellent performance : high temperature resistance - long-term use temperature of 200~260 degrees, low temperature resistance - still soft at -100 degrees; corrosion resistance - resistance to aqua regia and all organic solvents; Weather resistance - the best aging life in plastics; high lubricity - with the smallest coefficient of friction ( 0.04 ) in plastics; non-stick - with the smallest surface tension in solid materials without sticking to anything; non-toxic - physiologically inert; Excellent electrical properties, is an ideal Class C insulating material.

Post time: Oct-13-2022