-

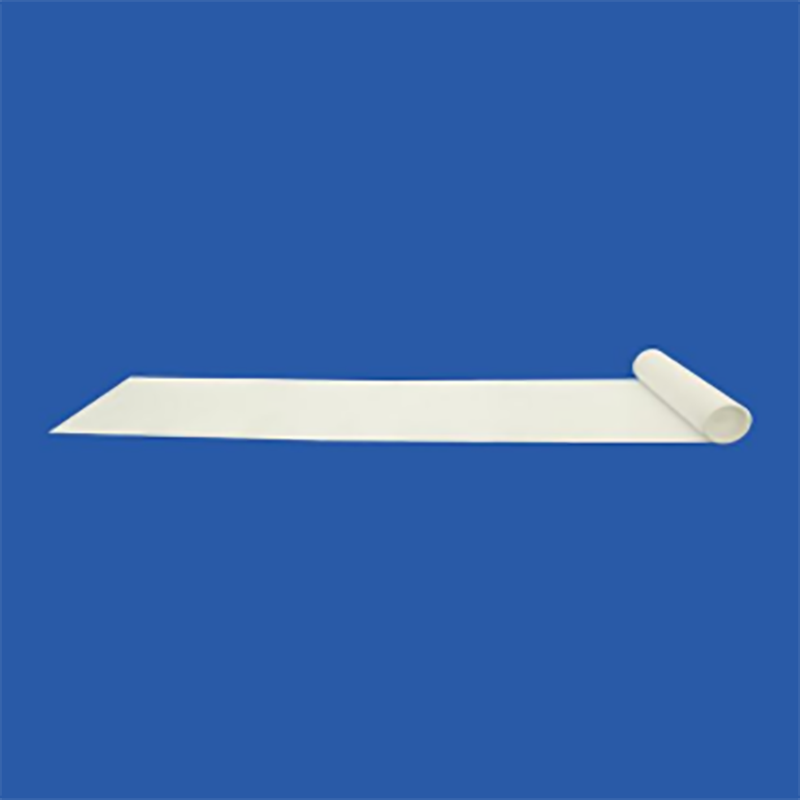

PTFE sheet: its applications in various industries

PTFE, or polytetrafluoroethylene, is a high-performance fluoropolymer widely used in various industries. PTFE sheeting is a form of polytetrafluoroethylene known for its superior properties and is highly sought after for its use as an insulation material and anti-stick c...Read more -

How does PTFE gland packing work?

PTFE gland packing is an efficient and reliable sealing solution used in a wide variety of industrial applications. It provides excellent sealing performance and durability, making it the first choice for sealing shafts and valve stems. In this article, we'll explore how...Read more -

What is PTFE lined steel?Comprehensive guide

PTFE lined steel pipe plays a vital role in various industries due to its superior chemical resistance, durability and reliability. These pipes are widely used in applications where corrosive fluids need to be transported. In this article, we will take an in-depth look a...Read more -

Features of Horizontal Storage Tank Lined With PTFE Sheet

Horizontal tanks lined with PTFE sheets are a premium and reliable solution for storing corrosive and high temperature chemicals. PTFE sheet stands for polytetrafluoroethylene, which is often used in industrial settings due to its unique properties and capabilities. In t...Read more -

Application of ptfe lined vessel

A PTFE lined vessel is a highly specialized piece of equipment that is used for a wide range of applications in many different industries. Its popularity lies in its ability to provide exceptional chemical resistance and inertness, making it an ideal choice for highly co...Read more -

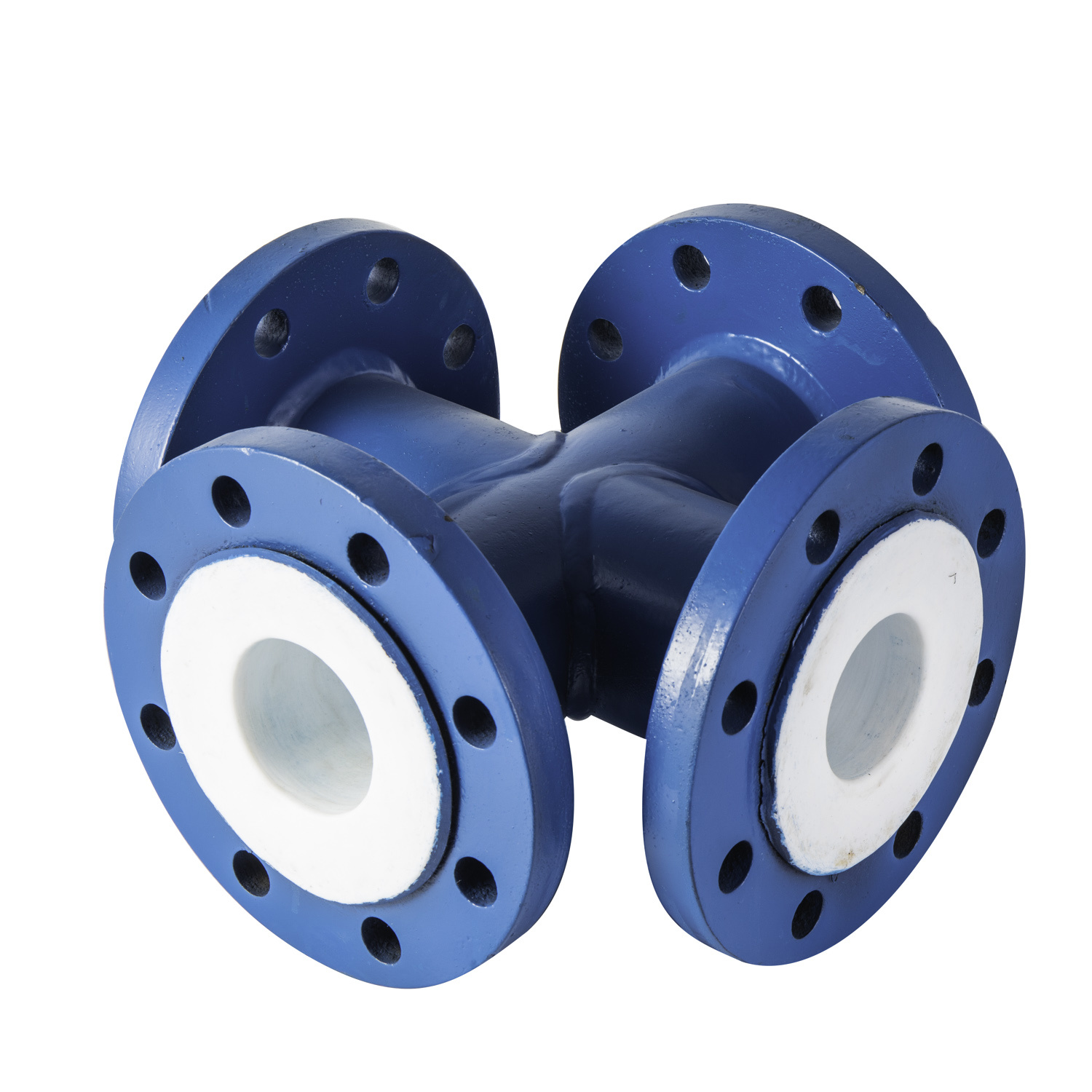

What is PTFE/PFA Lined Equal Tee Stainless Steel Pipe Fittings?

When it comes to industrial applications that involve the handling of corrosive media, finding suitable pipe fittings can be a daunting task. However, one option that has gained popularity due to its excellent corrosion resistance properties is PTFE/PFA lined equal tee s...Read more -

Top 10 Applications of Virgin PTFE Teflon / Etched PTFE Sheet

PTFE sheet is an incredibly versatile and useful material that has found its way into a vast number of different applications over the years. Whether you're working in the atomic energy industry or simply trying to find a way to insulate your electrical wiring, PTFE shee...Read more -

Five Features of Plastic Pall Ring

Plastic Pall Rings are one of the most widely used types of tower packing materials in industrial applications. These rings boast of several features that make them ideal for use in chemical, petrochemical, and pharmaceutical processes. In this article, we will discuss t...Read more -

Advantages of PTFE Lining Steel Pipes

PTFE-lined steel pipe is rapidly overtaking unlined steel pipe for a number of reasons. The PTFE lining helps strengthen the steel pipe, making it more durable and longer lasting, while providing several advantages. First, PTFE lined steel pipe is highly resistant to cor...Read more -

Why choose Yihao

When it comes to PTFE piping systems, there is only one company worth considering——Jiangsu Yihao Fluorine Plastic Manufacturing Co., Ltd. In the past 20 years, Yihao has been a leading supplier of PTFE piping systems in China with its strong technical force and strong technical strength. Advanced...Read more -

Five application fields of PTFE

PTFE has a wide range of applications, it can be used in medical equipment, printing, paper, fiber industry, chemical industry, food industry, household appliances, plastics, rubber industry, electronics, automobile industry, etc. PTFE has a wide range of applications, it can be used in medical e...Read more -

The use and advantages of PTFE board

All kinds of PTFE products have played a pivotal role in the national economic fields such as chemical industry, machinery, electronics, electrical appliances, military industry, aerospace, environmental protection and bridges. Tetrafluoroethylene board is suitable for the temperature of -180℃~+2...Read more